PRINT CAPABILITIES

We combine many specialty services in house. Letterpress printing, foil stamping, thermography, die cutting, edge coloring, and gilding are all processes we do in house on top of offset lithography and digital printing. >more

CUSTOM DESIGN

We specialise in creating great design work tailored to your specific needs, and well suited for our specialised printing techniques. >more

PRODUCTION CONSULTANCY

With over 30 years of production experience and designers ourselves, we are able to bridge the needs of both designers and brands through our technical expertise. >more

PRINT CAPABILITIES

LETTERPRESS PRINTING

Letterpress printing has been credited with many things, most important of which is making printed material more widely available. Traditional letterpress printing involves inking raised metal types, and rolling or pressing paper against it to form an impression. This was the primary means of mass communication for over 500 years until the introduction of the modern printing technology that we know today as lithographic / offset printing.

Today, letterpress printing is highly valued by artisans. High quality papers and inks are used to create an especially lush impression. Items printed by letterpress can be readily identified by the impressions of the letters, which punch into the paper slightly to create greater visual definition.

Check out this great video documentary on letterpress printing on Youtube.

Also known as: Relief Printing, Deboss Printing, Deep Relief Printing, Embossed Printing

PRINT CAPABILITIES

DIGITAL PRINT

Digital Printing is an extremely straight forward process. It does not require printing plates and ink that lithography requires. Instead, it uses a digital file to send information directly to the printer where toner ink is applied and then fused onto the paper. Digital prints are made up of the four process colours (CMYK). Digital printing is extremely versatile, allowing for prints on a wide range of materials. We love to combine digital with lithographic / offset and digital printing, to produce very interesting projects.

Also known as: CMYK Printing, Xerox

PRINT CAPABILITIES

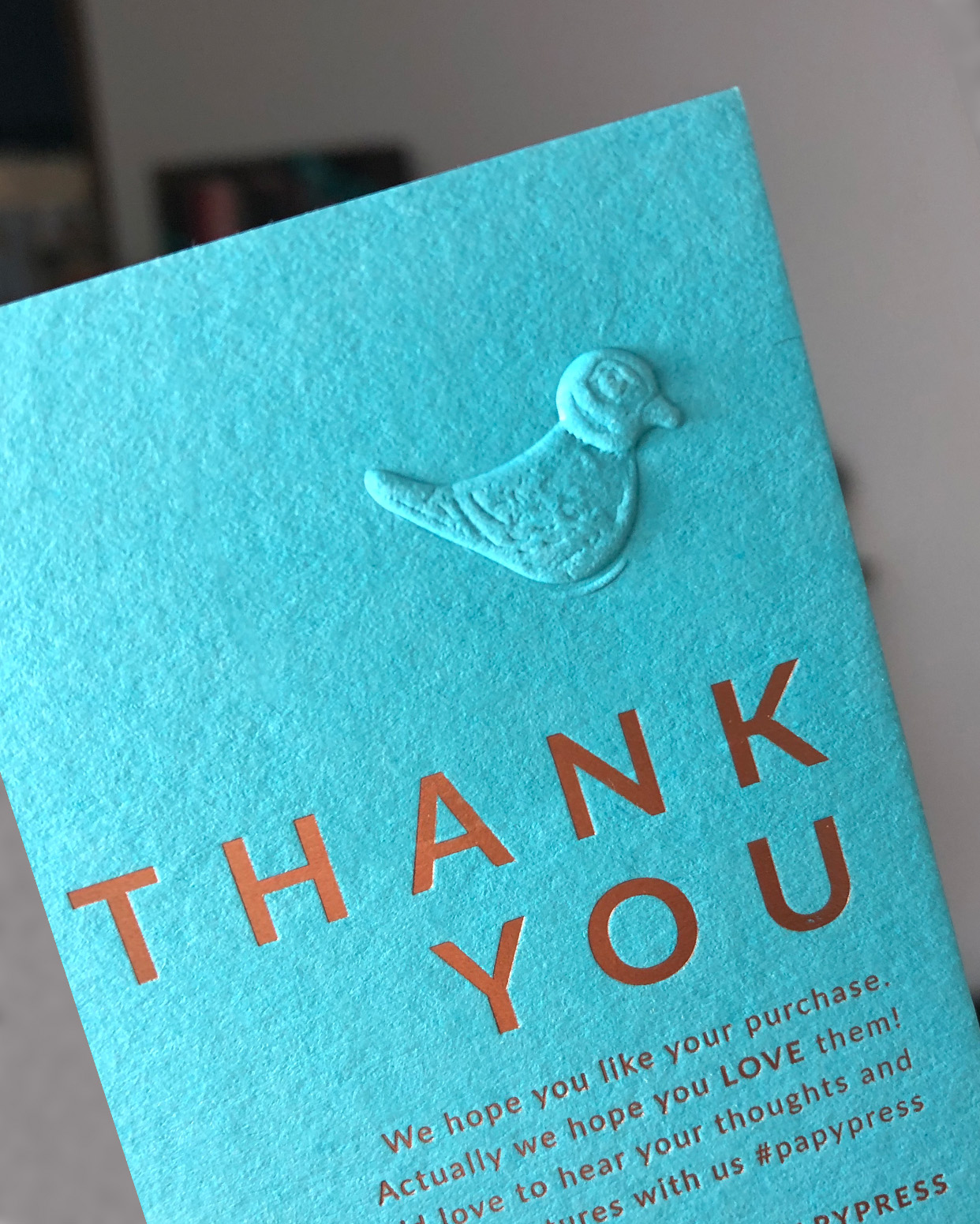

HOT STAMPING / HOLOGRAPHIC FOIL PRINTING

Hot stamping is undoubtedly one of the most beautiful type of finishing. Shocking pink, metallic rose gold and matt white are just some of the unique colours that we have available for hot foil stamping. With foil stamping, we are able to print on materials such as leather, birchwood and even napkins!

We have worked with a wide range of foils from Kurz (Germany), Foilco (UK) and Nakai (Japan).

Also known as: Hot Stamping, Hot Foiling

PRINT CAPABILITIES

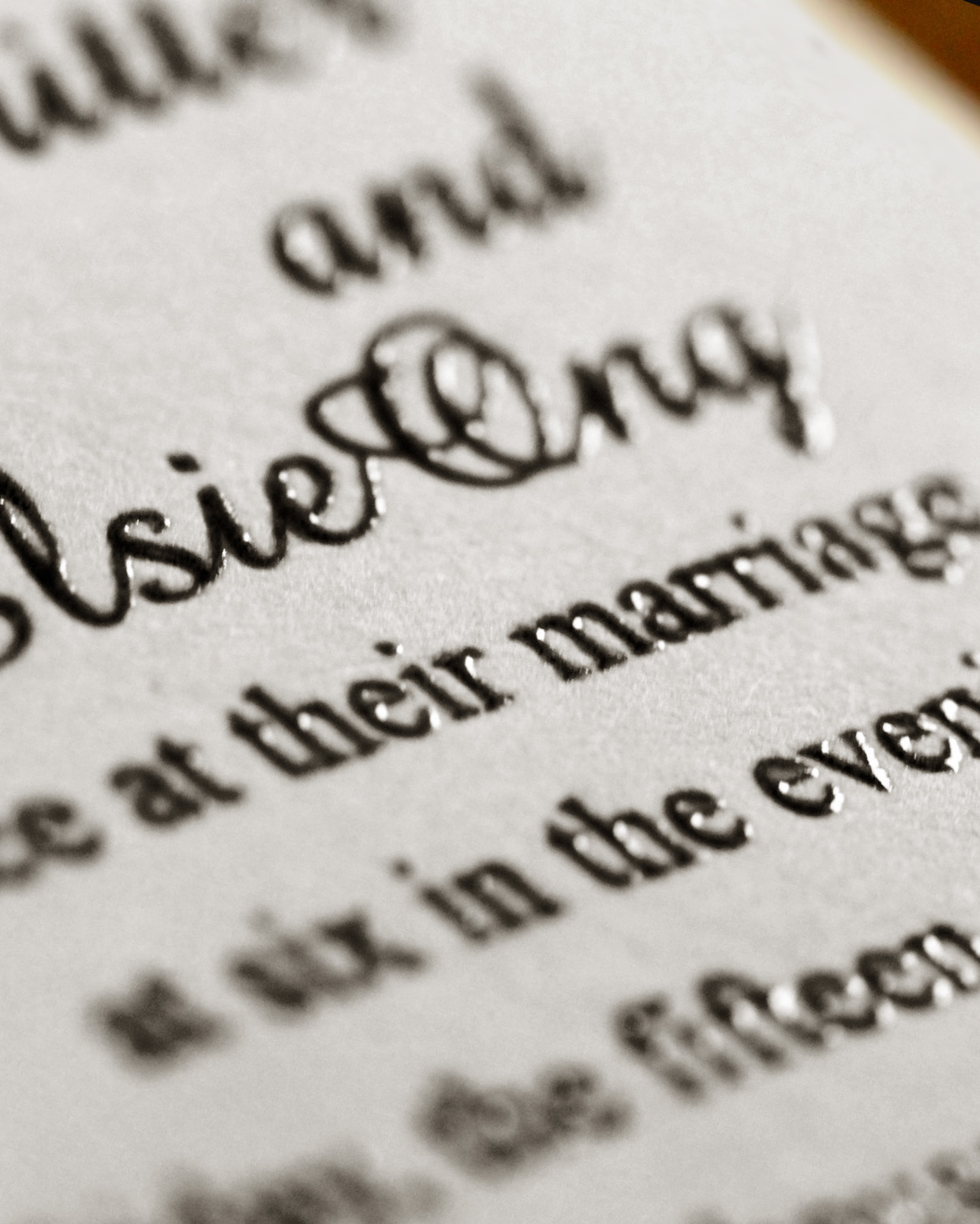

THERMOGRAPHY PRINTING

For those in the know, this used to be one of the most elusive of print methods after letterpress printing. You have seen it somewhere, but not sure where and can't find anyone who can do it or do it well. The rumour mill has it that this form of printing no longer exists. But behold! PyPr does thermography printing and it is alive and kicking back in our studio! This form of printing is a painful process for any printer, but the hardwork definitely pays off when we hear the "oohs" and "ahhs" from our clients.

Thermography or Raised Ink Printing is produced using a manual powdering process. The material with the wet ink is dipped into the embossing powder. The sheet is then tilted back and forth, rolling the powder across the image for it to adhere to. The powdered sheet is then fed into a heating system which creates the raised text effect.

It is commonly used on wedding invitations, letterheads, business cards and greetings cards.

Also known as: Raised Ink Printing, Thermal Printing, Emboss Text Printing

PRINT CAPABILITIES

DIE CUTTING / CUSTOM SHAPE PRINTING

Started as a process of cutting leather for the shoe industry, it is now sophisticated enough to cut the different shapes and sizes for your bespoke stationery as well. By making a custom die or knife, we are able to produce an infinite number of designs for your very own unique set of stationery.

Also known as: Punch Out

PRINT CAPABILITIES

3D Embossing

Besides regular embossing, 3D embossing is a new capability that we have added to our repertoire in the last 2 years. It adds a completely new dimension to your prints by featuring more layers and depths to the design, creating a much more three-dimensional experience for the beholder.

Also known as: Embossing, 3D Stamping

PRINT CAPABILITIES

Gold Foil Gliding / Edge Colouring

Reviving the centuries old tradition of gilding locally in our workshop, we have managed to preserve this beautiful art and have perfected it over the years.

A tedious process of clamping the material in a block, sanding all the edges down to achieve a smooth surface and finally foil gilding each edge one at a time.

Gilding Colours:

Gold, Silver, Rose Gold, Copper, Bronze and Laser.

Also known as: Edging, Colour Edging, Foil Edge, Edge Stamping, Metallic Foil Gilding

Custom Design

The following is a run-down of how our custom design process works.

ONE – Let’s chat!

The first thing we do is have a conversation with you to establish your requirements. This can be a scheduled phone call, email, or an in-studio meeting. We usually prefer an in-studio visit where possible since it's almost always easier to have all our samples on hand to base our discussion on. Nothing like having an actual feel for the physical paper. We will talk through the items you wish to have printed, your preferred design style and discuss a project budget.

TWO – How much?

Once we’ve had our conversation with you, we will email a quotation based on your requested scope-of-work. You must approve this quote to proceed. Once we receive your confirmation and a 50% deposit we can begin the design process.

THREE – We design.

This is the fun part. We highly encourage lots of idea sharing so that we can ensure both parties are on the same page. We will prepare a mood board with 2-3 design options, you pick a direction and we do up 2 variations of the selected design style based on your feedback. The entire design process, with rounds of revisions typically takes 2 – 4 weeks. During this process we can provide guidance about how your design choices will affect production costs, so you can stay within your budget.

FOUR – Production

Production begins when you have signed off on the final artwork and digital proof (if required and time permits) and make the necessary payment. 10-12 business days is the typical production time.

Submit an estimate request here to begin the process.

PRINT PRODUCTION CONSULTANCY

DESIGN & PRODUCTION EXPERIENCE

During the design process, there are ways to optimise and simplify production processes simply by making good informed decisions. Many designers are unaware of the additional cost that has been incurred unnecessarily due to ill prepared artworks. When materials are expensive, the last thing one would want to do is to waste material. Sometimes choosing an alternative print method could prove to be a more economical choice while still fulfilling the project requirements. A combination of these skills and a prompt decision making process can make production a smoother and pain-free process.

Artwork has been approved and it's time for print. As simple as it may sound but it's more than just click and send. There are plenty of details to keep in mind when it comes to preparing your project for printing. Have you taken note of all the do's and don'ts? Have you submitted the file as an RGB or CMYK format? Have all the necessary bleeds been added? Will you be using digital printing or Pantone offset Printing?

When possible, production consultancy should happen before or at least during the design process. Not doing so may mean major modifications to be made just before production. It's never pleasant when a designer has to inform a client that either the design has to be changed or the chosen production method has to be changed.

With over 30 years of experience in the industry, bring us in early in your design process to ensure a smooth process for your projects.